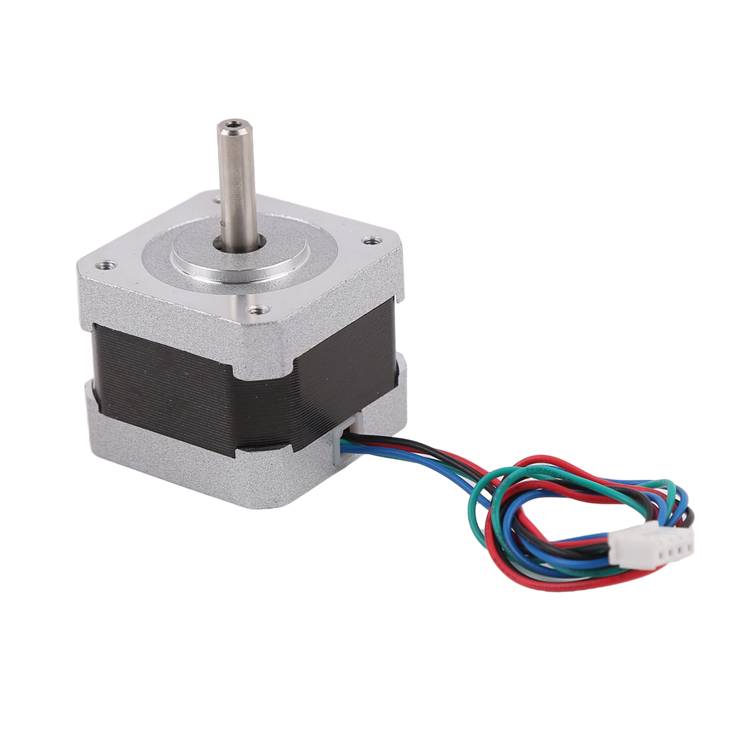

ໃນຖານະເປັນອົງປະກອບການປະຕິບັດດິຈິຕອນ, stepper motor ໄດ້ຖືກນໍາໃຊ້ຢ່າງກວ້າງຂວາງໃນລະບົບການຄວບຄຸມການເຄື່ອນໄຫວ. ຜູ້ໃຊ້ຫຼາຍຄົນແລະຫມູ່ເພື່ອນໃນການນໍາໃຊ້ມໍເຕີ stepper, ຮູ້ສຶກວ່າມໍເຕີເຮັດວຽກດ້ວຍຄວາມຮ້ອນຂະຫນາດໃຫຍ່, ຫົວໃຈແມ່ນບໍ່ຄ່ອຍເຊື່ອງ່າຍໆ, ບໍ່ຮູ້ວ່າປະກົດການນີ້ແມ່ນເປັນປົກກະຕິ. ໃນຄວາມເປັນຈິງ, ຄວາມຮ້ອນແມ່ນປະກົດການທົ່ວໄປຂອງມໍເຕີ stepper, ແຕ່ລະດັບຄວາມຮ້ອນໃດທີ່ຖືວ່າເປັນປົກກະຕິ, ແລະວິທີການຫຼຸດຜ່ອນຄວາມຮ້ອນຂອງມໍເຕີ stepper?

ຫນຶ່ງໃນ, ເພື່ອເຂົ້າໃຈວ່າເປັນຫຍັງ motor stepper ຈະຮ້ອນຂຶ້ນ.

ສໍາລັບທຸກປະເພດຂອງມໍເຕີ stepper, ພາຍໃນແມ່ນປະກອບດ້ວຍແກນທາດເຫຼັກແລະ winding coil. ຄວາມຕ້ານທານ winding, ພະລັງງານຈະຜະລິດການສູນເສຍ, ການສູນເສຍຂະຫນາດແລະການຕໍ່ຕ້ານແລະປະຈຸບັນແມ່ນອັດຕາສ່ວນກັບສີ່ຫຼ່ຽມມົນ, ນີ້ແມ່ນສິ່ງທີ່ພວກເຮົາມັກຈະເອີ້ນວ່າການສູນເສຍທອງແດງ, ຖ້າຫາກວ່າປະຈຸບັນບໍ່ໄດ້ມາດຕະຖານ DC ຫຼື sine wave, ຍັງຈະຜະລິດການສູນເສຍປະສົມກົມກຽວ; core hysteresis eddy ຜົນກະທົບໃນປະຈຸບັນ, ໃນສະຫນາມແມ່ເຫຼັກສະລັບກັນຍັງຈະຜະລິດການສູນເສຍ, ຂະຫນາດຂອງວັດສະດຸ, ໃນປະຈຸບັນ, ຄວາມຖີ່, ແຮງດັນທີ່ກ່ຽວຂ້ອງກັບການສູນເສຍທາດເຫຼັກ. ການສູນເສຍທອງແດງແລະການສູນເສຍທາດເຫຼັກຈະຖືກສະແດງອອກໃນຮູບແບບຂອງການຜະລິດຄວາມຮ້ອນ, ດັ່ງນັ້ນຜົນກະທົບຕໍ່ປະສິດທິພາບຂອງມໍເຕີ.

Stepping motor ໂດຍທົ່ວໄປປະຕິບັດຕາມຄວາມຖືກຕ້ອງຂອງຕໍາແຫນ່ງແລະຜົນຜະລິດຂອງແຮງບິດ, ປະສິດທິພາບແມ່ນຂ້ອນຂ້າງຕ່ໍາ, ປະຈຸບັນໂດຍທົ່ວໄປແມ່ນຂະຫນາດໃຫຍ່, ແລະອົງປະກອບປະສົມກົມກຽວສູງ, ຄວາມຖີ່ຂອງປະຈຸບັນສະລັບກັບຄວາມໄວແລະການປ່ຽນແປງ, ສະນັ້ນ stepping motors ໂດຍທົ່ວໄປມີສະຖານະການຄວາມຮ້ອນ, ແລະສະຖານະການແມ່ນຮ້າຍແຮງກວ່າ motor AC ທົ່ວໄປ.

二, ການຄວບຄຸມຄວາມຮ້ອນ motor stepper ພາຍໃນຂອບເຂດທີ່ສົມເຫດສົມຜົນ.

ຄວາມຮ້ອນຂອງມໍເຕີອະນຸຍາດໃຫ້ຢູ່ໃນຂອບເຂດໃດກໍ່ຕາມ, ສ່ວນໃຫຍ່ແມ່ນຂຶ້ນກັບລະດັບ insulation ພາຍໃນຂອງມໍເຕີ. insulation ພາຍໃນບໍ່ໄດ້ຖືກທໍາລາຍຈົນກ່ວາມັນຢູ່ໃນອຸນຫະພູມສູງ (ສູງກວ່າ 130 ອົງສາ). ດັ່ງນັ້ນຕາບໃດທີ່ພາຍໃນບໍ່ເກີນ 130 ອົງສາ, ມໍເຕີຈະບໍ່ເສຍຫາຍ, ແລະຫຼັງຈາກນັ້ນອຸນຫະພູມຫນ້າດິນຈະຕໍ່າກວ່າ 90 ອົງສາ. ດັ່ງນັ້ນ, ອຸນຫະພູມດ້ານ motor stepper ຂອງ 70-80 ອົງສາແມ່ນປົກກະຕິ. ວິທີການວັດແທກອຸນຫະພູມແບບງ່າຍດາຍດ້ວຍເຄື່ອງວັດແທກອຸນຫະພູມ, ທ່ານຍັງສາມາດພິຈາລະນາປະມານ: ດ້ວຍມືສາມາດສໍາຜັດໄດ້ຫຼາຍກວ່າ 1-2 ວິນາທີ, ບໍ່ເກີນ 60 ອົງສາ; ດ້ວຍມືສາມາດແຕະພຽງແຕ່, ປະມານ 70-80 ອົງສາ; ສອງສາມຢອດຂອງນ້ໍາ vaporized ຢ່າງໄວວາ, ມັນແມ່ນຫຼາຍກ່ວາ 90 ອົງສາ; ແນ່ນອນ, ທ່ານຍັງສາມາດໃຊ້ປືນອຸນຫະພູມເພື່ອກວດຫາ.

三, ການໃຫ້ຄວາມຮ້ອນ motor stepper ກັບການປ່ຽນແປງຄວາມໄວ.

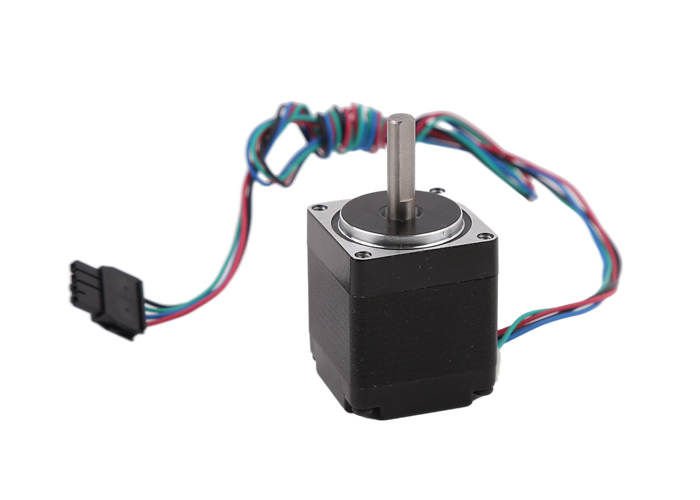

ໃນເວລາທີ່ການນໍາໃຊ້ເຕັກໂນໂລຊີຂັບໃນປະຈຸບັນຄົງທີ່, ມໍເຕີ stepper ໃນ static ແລະຄວາມໄວຕ່ໍາ, ປະຈຸບັນຈະຮັກສາຂ້ອນຂ້າງຄົງທີ່ເພື່ອຮັກສາຜົນຜະລິດ torque ຄົງທີ່.

ເມື່ອຄວາມໄວສູງເຖິງລະດັບທີ່ແນ່ນອນ, ທ່າແຮງດ້ານກົງກັນຂ້າມພາຍໃນມໍເຕີເພີ່ມຂຶ້ນ, ກະແສໄຟຟ້າຈະຄ່ອຍໆຫຼຸດລົງ, ແລະແຮງບິດກໍ່ຈະຫຼຸດລົງ. ດັ່ງນັ້ນ, ການຜະລິດຄວາມຮ້ອນເນື່ອງຈາກການສູນເສຍທອງແດງແມ່ນກ່ຽວຂ້ອງກັບຄວາມໄວ.

ການຜະລິດຄວາມຮ້ອນໂດຍທົ່ວໄປແມ່ນສູງຢູ່ທີ່ຄວາມໄວຄົງທີ່ແລະຕ່ໍາແລະຕ່ໍາໃນຄວາມໄວສູງ. ແຕ່ການສູນເສຍທາດເຫຼັກ (ເຖິງແມ່ນວ່າອັດຕາສ່ວນຫນ້ອຍ) ການປ່ຽນແປງບໍ່ແມ່ນກໍລະນີ, ແລະຄວາມຮ້ອນຂອງມໍເຕີທັງຫມົດແມ່ນຜົນລວມຂອງສອງ, ດັ່ງນັ້ນຂ້າງເທິງແມ່ນພຽງແຕ່ສະຖານະການທົ່ວໄປ.

四, ຜົນກະທົບຂອງຄວາມຮ້ອນ

ຄວາມຮ້ອນຂອງມໍເຕີ, ເຖິງແມ່ນວ່າໂດຍທົ່ວໄປບໍ່ມີຜົນກະທົບຕໍ່ຊີວິດຂອງມໍເຕີ, ລູກຄ້າສ່ວນໃຫຍ່ບໍ່ຈໍາເປັນຕ້ອງເອົາໃຈໃສ່. ຢ່າງໃດກໍ່ຕາມ, ຄວາມຮ້ອນທີ່ຮ້າຍແຮງຈະນໍາເອົາຜົນກະທົບທາງລົບບາງຢ່າງ.

ເຊັ່ນ: ພາກສ່ວນພາຍໃນຂອງຕົວຄູນການຂະຫຍາຍຄວາມຮ້ອນ motor ຂອງຄວາມກົດດັນໂຄງສ້າງທີ່ແຕກຕ່າງກັນທີ່ເກີດຈາກການປ່ຽນແປງຂອງຊ່ອງຫວ່າງອາກາດພາຍໃນແລະການປ່ຽນແປງຂະຫນາດນ້ອຍຈະສົ່ງຜົນກະທົບຕໍ່ການຕອບສະຫນອງແບບເຄື່ອນໄຫວຂອງມໍເຕີ, ຄວາມໄວສູງຈະງ່າຍທີ່ຈະສູນເສຍຂັ້ນຕອນ.

ຕົວຢ່າງອີກອັນຫນຶ່ງແມ່ນວ່າບາງໂອກາດບໍ່ອະນຸຍາດໃຫ້ມີຄວາມຮ້ອນຫຼາຍເກີນໄປຂອງມໍເຕີ, ເຊັ່ນອຸປະກອນການແພດແລະອຸປະກອນການທົດສອບຄວາມແມ່ນຍໍາສູງ. ດັ່ງນັ້ນ, ຄວາມຮ້ອນຂອງມໍເຕີຄວນຈະເປັນການຄວບຄຸມທີ່ຈໍາເປັນ.

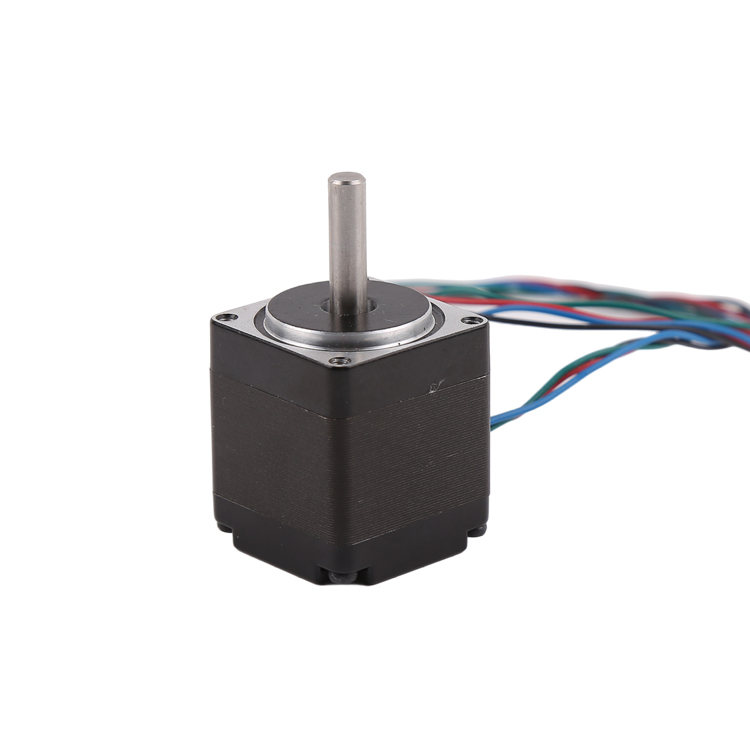

五, ຫຼຸດຜ່ອນຄວາມຮ້ອນຂອງມໍເຕີ.

ຫຼຸດຜ່ອນຄວາມຮ້ອນ, ແມ່ນເພື່ອຫຼຸດຜ່ອນການສູນເສຍທອງແດງແລະການສູນເສຍທາດເຫຼັກ. ການຫຼຸດຜ່ອນການສູນເສຍທອງແດງມີສອງທິດທາງ, ຫຼຸດຜ່ອນຄວາມຕ້ານທານແລະປະຈຸບັນ, ເຊິ່ງຮຽກຮ້ອງໃຫ້ມີການເລືອກຄວາມຕ້ານທານຂະຫນາດນ້ອຍແລະປະຈຸບັນການຈັດອັນດັບຫຼາຍເທົ່າທີ່ເປັນໄປໄດ້ໃນການຄັດເລືອກ motors ຂະຫນາດນ້ອຍ, motors ສອງໄລຍະ, ສາມາດນໍາໃຊ້ໃນ motors ຊຸດບໍ່ຈໍາເປັນຕ້ອງ motor ຂະຫນານ.

ແຕ່ນີ້ມັກຈະຂັດກັບຄວາມຕ້ອງການຂອງແຮງບິດແລະຄວາມໄວສູງ.

ສໍາລັບມໍເຕີໄດ້ຖືກເລືອກ, ມັນຄວນຈະເຮັດໃຫ້ການນໍາໃຊ້ຢ່າງເຕັມທີ່ຂອງການຄວບຄຸມເຄິ່ງປະຈຸບັນອັດຕະໂນມັດຂອງໄດແລະຟັງຊັນອອຟໄລ, ອະດີດອັດຕະໂນມັດຫຼຸດລົງປະຈຸບັນໃນເວລາທີ່ມໍເຕີຢູ່ໃນສະພາບຄົງທີ່, ສຸດທ້າຍພຽງແຕ່ຕັດກະແສໄຟຟ້າ.

ນອກຈາກນັ້ນ, ໄດແບ່ງອອກຢ່າງດີເນື່ອງຈາກຮູບແບບຄື້ນໃນປະຈຸບັນຢູ່ໃກ້ກັບ sinusoidal, ຄວາມກົມກຽວຫນ້ອຍ, ຄວາມຮ້ອນຂອງມໍເຕີຈະຫນ້ອຍລົງ. ບໍ່ມີວິທີການຫຼາຍທີ່ຈະຫຼຸດຜ່ອນການສູນເສຍທາດເຫຼັກ, ລະດັບແຮງດັນແມ່ນກ່ຽວຂ້ອງກັບມໍເຕີຂອງໄດແຮງດັນສູງ, ເຖິງແມ່ນວ່າມັນຈະນໍາເອົາລັກສະນະຄວາມໄວສູງຂອງການເພີ່ມປະສິດທິພາບ, ແຕ່ຍັງເຮັດໃຫ້ຄວາມຮ້ອນເພີ່ມຂຶ້ນ.

ດັ່ງນັ້ນ, ພວກເຮົາຄວນເລືອກລະດັບແຮງດັນຂອງໄດທີ່ເຫມາະສົມ, ໂດຍຄໍານຶງເຖິງຄວາມໄວສູງ, ຄວາມລຽບແລະຄວາມຮ້ອນ, ສິ່ງລົບກວນແລະຕົວຊີ້ວັດອື່ນໆ.

ເວລາປະກາດ: ກັນຍາ-13-2024